Lithium battery manufacturers in Europe

The lithium battery manufacturing industry in Europe is experiencing significant growth, driven by the increasing demand for electric vehicles (EVs), renewable energy storage, and other emerging applications. This expansion is not only fueled by the need to reduce carbon emissions and combat climate change but also by the region's efforts to establish a more sustainable and self-sufficient supply chain for critical raw materials. Below is an expanded discussion on lithium battery manufacturers in Europe, focusing on their development, technological advancements, and market trends.

Development of Lithium Battery Manufacturers in Europe

In recent years, Europe has witnessed a surge in the number of lithium battery manufacturers, with many new players entering the market and established companies expanding their production capacities. This growth is driven by several factors, including government incentives for EV adoption, investments in research and development (R&D), and the need to reduce dependency on imported raw materials.

One of the key developments in the European lithium battery manufacturing industry is the increasing focus on recycling. With the rapid growth in EV sales and the impending need for battery replacements, the demand for lithium-ion battery recycling is expected to rise sharply in the coming years. To meet this demand, many European countries are investing in recycling facilities and technologies, aiming to achieve high recovery rates and minimize environmental impact.

Technological Advancements

European lithium battery manufacturers are continuously investing in R&D to improve battery performance, reduce costs, and enhance safety. Key technological advancements include:

Improved Battery Chemistry: Manufacturers are developing new battery chemistries that offer higher energy density, longer cycle life, and faster charging times. For instance, solid-state batteries, which use solid electrolytes instead of liquid ones, are being researched extensively due to their potential to offer significant improvements in safety and performance.

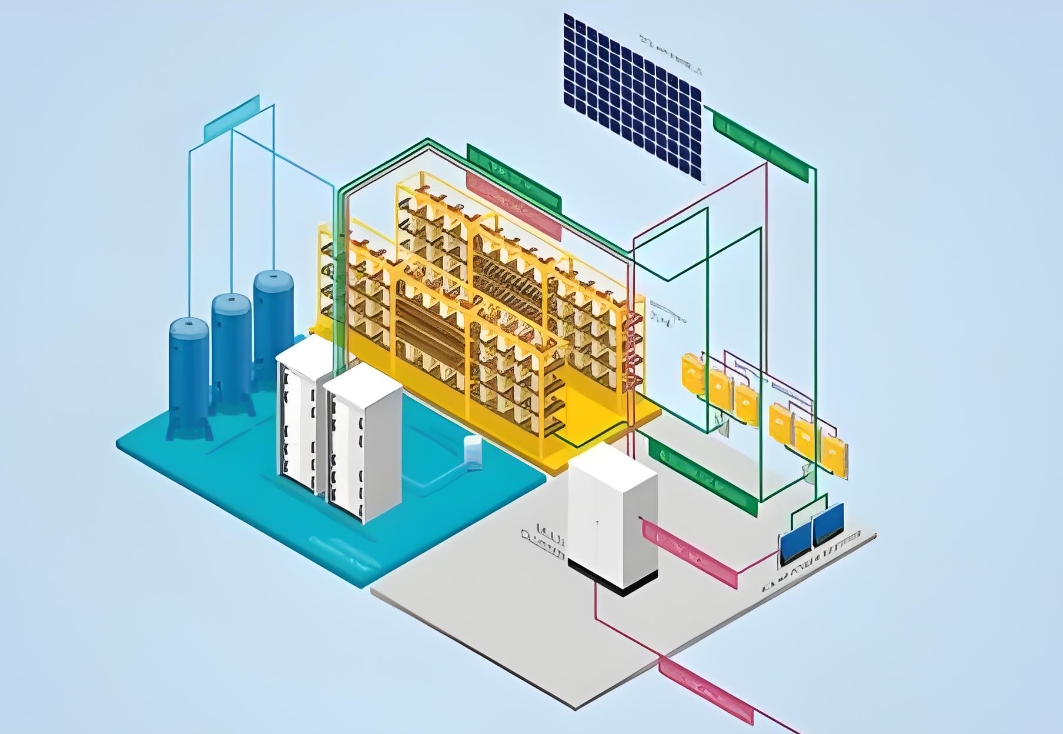

Advanced Manufacturing Techniques: European companies are adopting advanced manufacturing techniques, such as automation and robotics, to improve production efficiency and reduce costs. These techniques also help in achieving higher precision and consistency in battery manufacturing.

Smart Battery Management Systems (BMS): BMS play a crucial role in monitoring and managing battery performance, ensuring optimal operation and safety. European manufacturers are developing sophisticated BMS that can predict and prevent potential failures, thus extending battery life and reducing maintenance costs.

Market Trends

The European lithium battery market is experiencing several trends that are shaping the industry's future:

Rising Demand for EVs: The European Union (EU) has set ambitious targets for reducing greenhouse gas emissions, with a significant focus on promoting EV adoption. This has led to a surge in demand for lithium batteries, particularly in the automotive sector.

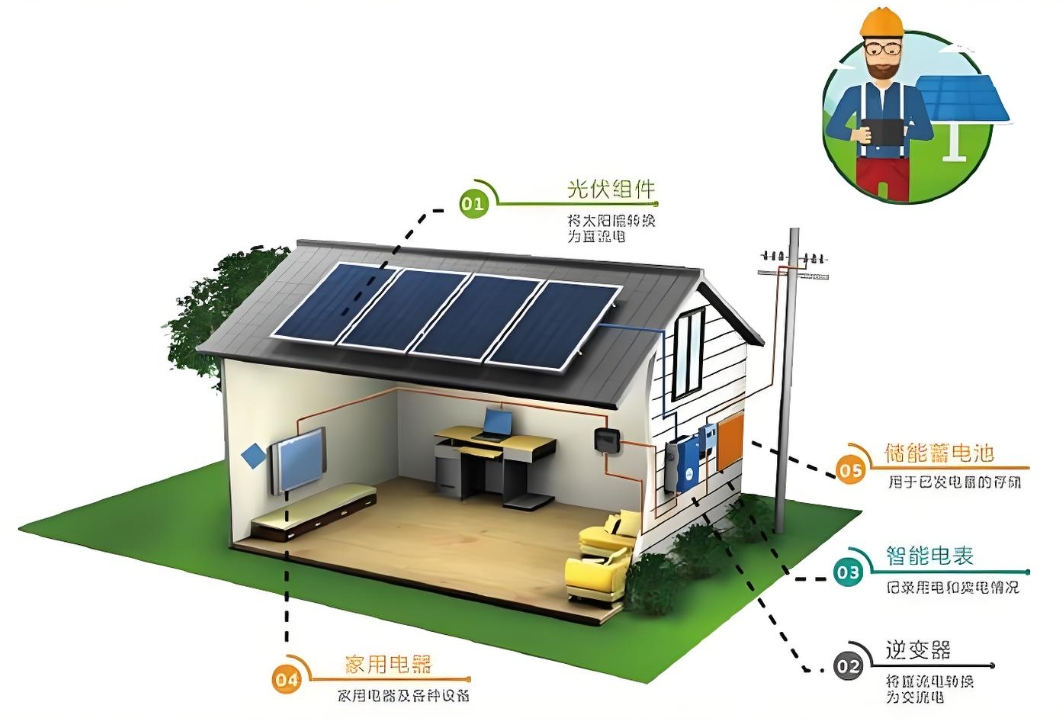

Development of Renewable Energy Storage: As Europe transitions to renewable energy sources, such as wind and solar, the need for energy storage solutions is increasing. Lithium batteries are well-suited for this purpose, offering high energy density and long-duration storage capabilities.

Investment in Battery Recycling: As mentioned earlier, the demand for lithium-ion battery recycling is expected to rise sharply in the coming years. European governments and private investors are pouring money into recycling facilities and technologies, aiming to create a circular economy for lithium batteries.

Collaboration and Partnerships: European lithium battery manufacturers are increasingly collaborating with research institutions, universities, and other stakeholders to accelerate technological advancements and drive innovation. These collaborations help in sharing knowledge, resources, and expertise, leading to faster development and commercialization of new battery technologies.

Key Players in the Industry

Several European companies are leading the charge in the lithium battery manufacturing industry. Some of the key players include:

Northvolt: Based in Sweden, Northvolt is one of the largest lithium battery manufacturers in Europe. The company focuses on producing high-quality lithium hydroxide and lithium carbonate, which are critical raw materials for lithium batteries. Northvolt is also expanding its recycling capabilities, aiming to create a circular economy for lithium batteries.

Umicore: Umicore is a Belgium-based company that specializes in the recycling and refining of critical raw materials, including lithium. The company has a significant presence in the lithium battery recycling market, offering advanced recycling technologies and solutions.

BASF: BASF, a German chemical company, has developed a new range of anode binders for lithium-ion batteries called Licity®. These binders improve battery performance, including higher capacity, increased cycle life, and reduced charging times. BASF is committed to aligning economic goals with environmental and social responsibility, making its products sustainable and eco-friendly.

EcoBat: EcoBat is a UK-based company that specializes in the recycling of lithium-ion batteries. The company is building a network of recycling facilities across Europe, aiming to achieve high recovery rates and minimize environmental impact. EcoBat is also developing new battery technologies, focusing on sustainability and performance.

Conclusion

The European lithium battery manufacturing industry is poised for significant growth in the coming years, driven by the increasing demand for EVs, renewable energy storage, and other emerging applications. With continuous investments in R&D, advanced manufacturing techniques, and recycling technologies, European manufacturers are well-positioned to meet this demand and drive innovation in the industry. Collaboration and partnerships among stakeholders will play a crucial role in accelerating technological advancements and creating a more sustainable and self-sufficient supply chain for critical raw materials.